QuakeWrap Blog

Insights, Case Studies, and Innovation in Infrastructure Technology

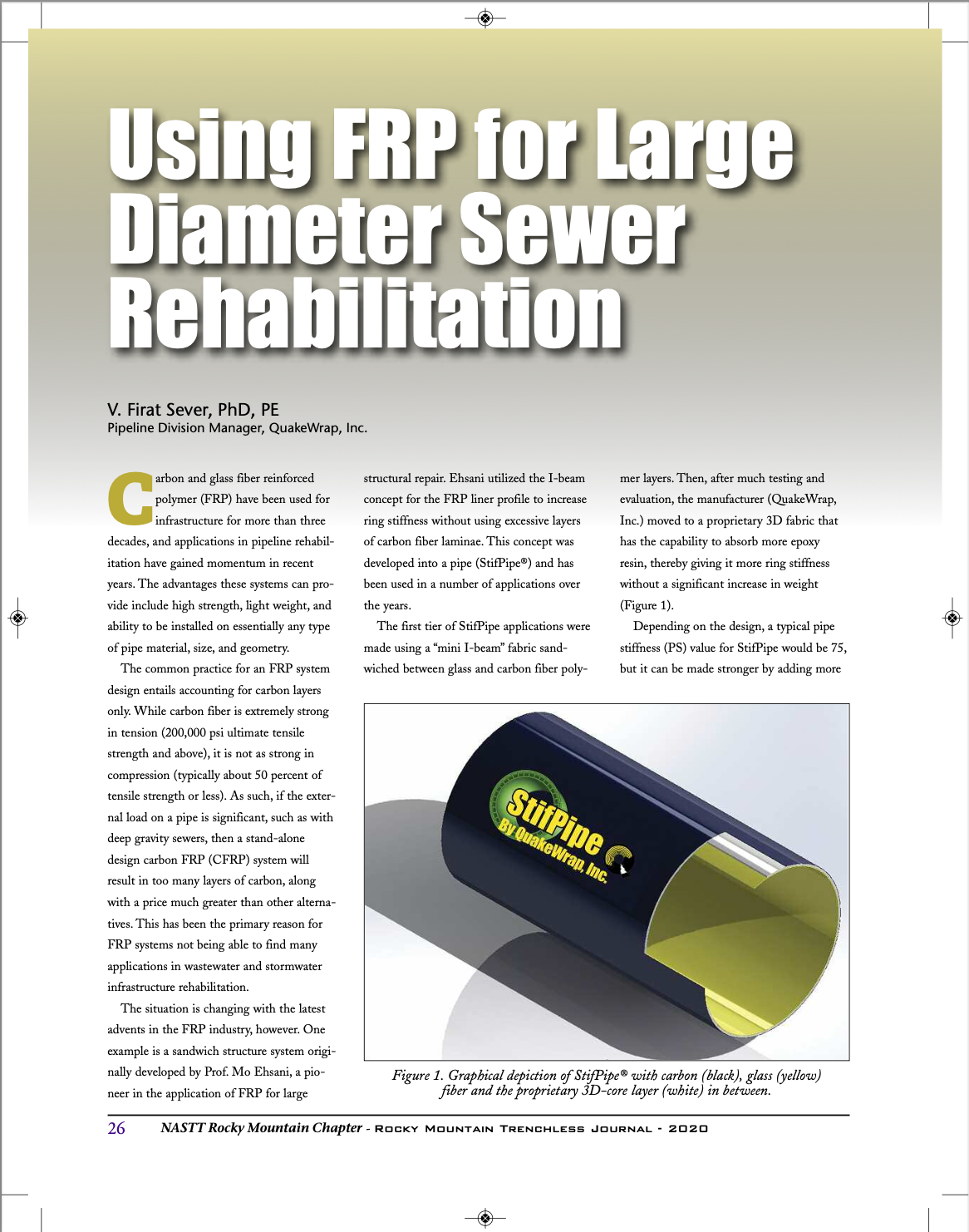

Using FRP for Large Diameter Sewer Rehabilitation

March 2, 2025 • V. Firat Sever

The document discusses the use of FRP (Fiber-Reinforced Polymer) tunnel repair using trenchless QuakeWrap technology in the I-35W/I-94 tunnel system in Minneapolis, Minnesota, addressing structural distress caused by erosion due to cycles of pressurization and depresurization. The installation involved wet layup methods with continuous moisture and temperature monitoring, ensuring compliance with engineering standards.

Healthcare Facilities (Hospitals/Medical Offices)

February 21, 2025 • Hui Zhou

QuakeWrap® provides fast, cost-effective Fiber Reinforced Polymer (FRP) solutions for healthcare facility repairs, including strengthening, seismic retrofitting, and corrosion damage. Their turnkey design-build service includes engineering, materials, and certified installation, minimizing disruptions. QuakeWrap® also partners with owners and contractors on specific project aspects like design, materials, or installation.

Building Rehab Solutions for Colleges and Universities

February 20, 2025 • Hui Zhou

QuakeWrap Wins Federal Research Grant to Explore Gas and Oil Pipeline Repair

June 12, 2020

The document highlights QuakeWrap Inc.'s participation in the U.S. DOT SBIR Phase 1 program to develop innovative solutions for pipe reinforcement using FRP materials, aiming to enhance transportation infrastructure safety and efficiency through commercializable technologies.

ASCE Life Member Status Awarded to FRP Pioneer, Innovator

May 24, 2019

The document announces that Prof. Mo Ehsani of QuakeWrap Inc., an ASCE Life Member since 2019, has been re-elected as a Life Member following his long career in civil engineering at the University of Michigan and the University of Arizona.

Timber Pile Repair Guide Features PileMedic

March 16, 2019 • Pile Buck Magazine

PileMedic® by QuakeWrap's extraordinary capability to completely encapsule corroded and damaged timber piles with extremely limited access is on full display in this informative guide published by Pile Buck magazine. PileMedic’s pile repair advantages are the featured photo illustrations in this dossier of all things marine timber piles, penned by the technical writers for Pile Buck.

Trenchless Technology PipeMedic Rehab Project of the Year

October 18, 2018

QuakeWrap’s large conveyance repair system rehabilitates a large gas pipe in New Jersey and wins Project of the Year recognition from Trenchless Technology magazine. The carbon FRP laminates used in this project are only 0.024 inches thick but are stronger than steel. You can read about this critical repair project here.

QuakeWrap Recognized for Exports, Global Economy Contributions

June 6, 2018

Arizona’s Joint Planning Advisory Council Sun Corridor Export Recognition Program for Economic Development for the Global Economy (EDGE) recognizes the export achievements of QuakeWrap, Inc., for 2017-18. The recognition is for overall export achievements benefiting Pima County as well as the global economy.

How carbon fiber repaired and strengthened 90-yearold steel penstock to be featured at HydroVision 2017

June 22, 2017

The document details the use of QuakeWrap’s FRP technology to repair and strengthen a 90-year-old steel penstock at Hydrovision International in Denver. It emphasizes how carbon fiber-reinforced polymer materials can enhance the penstock’s strength while ensuring it meets necessary standards for safety and compliance.

Kudos for QuakeWrap's In-House Construction Company

March 1, 2017

QuakeWrap’s in-house installation team, FRP Construction LLC, earns kudos from the Salt Lake City Department of Public Utilities for showing positive attitudes, job site sensitivity and installation diligence during a recent culvert repair job that involved running water, bad weather and other challenges.

SPiRe®, a new sheet pile repair system using PileMedic® technology, debuts at Underwater Intervention 2017

February 22, 2017

The document introduces SPiRe®, a new FRP-based system by QuakeWrap, Inc., designed to repair corroded steel sheet piles and seawalls with ease in both above and below water conditions. Lightweight panels simplify installation, and the system is exclusively available from PileMedic®. Highlighted as an innovative solution at UI2017, it represents a significant advancement in ocean engineering for restoring or repairing structures affected by corrosion.